Semiconductor Inspection

According to the link in the testing process, IC testing can be divided into design verification, front track measurement and back track detection. From the perspective of technical route principle, detection and measurement mainly include optical detection technology, electron beam detection technology and X-ray measurement technology, of which optical detection technology occupies a relatively large space.

The

Challenge

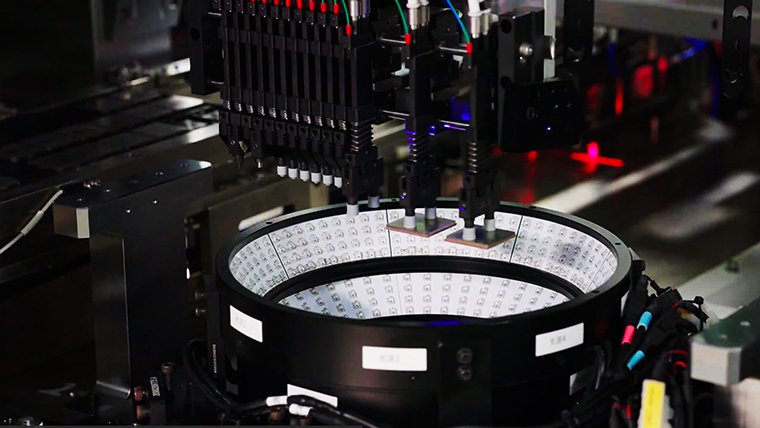

With the continuous development of the manufacturing industry and the improvement of product fineness, AOI optical inspection equipment needs to have higher accuracy and faster speed to meet the high efficiency and high precision inspection needs on the production line. With the development of artificial intelligence, machine learning and other technologies, AOI inspection equipment will be more intelligent, and can continuously improve the accuracy and stability of detection through self-learning and upgrading, while reducing the false detection and missed detection rate. In the future, it is believed that AOI inspection equipment will be further integrated, integrating a variety of testing technologies into one device, achieving multi-angle and multi-level testing, and improving the comprehensiveness and accuracy of testing.

-

Higher Inspection Accuracy

Higher Inspection Accuracy -

High-Efficiency Inspection Capability

High-Efficiency Inspection Capability -

Balancing Inspection Speed and Cost Efficiency

Balancing Inspection Speed and Cost Efficiency -

Modular Design to Meet Diverse Functional Requirements

Modular Design to Meet Diverse Functional Requirements

Discover how we

can help you?